Labs

Lyopho Lizer

This instrument is used to remove the moisture from the sample or substances

This instrument is used to remove the moisture from the sample or substances

Glove Box

This is use to create a N2 environment to avoid for contaminating of sample or substances .

This is use to create a N2 environment to avoid for contaminating of sample or substances .

Chemical Vapor Deposition Set-up

Chemical vapor deposition (CVD) is a chemical process used to produce high quality, high-performance, solid materials. The process is often used to produced thin film like Graphene, MoS2, WS2, MoSe2, WSe2 on desired substrate. In CVD, the substrate is exposed to one or more precursors , which react on the substrate surface to produce the desired deposit.

Chemical vapor deposition (CVD) is a chemical process used to produce high quality, high-performance, solid materials. The process is often used to produced thin film like Graphene, MoS2, WS2, MoSe2, WSe2 on desired substrate. In CVD, the substrate is exposed to one or more precursors , which react on the substrate surface to produce the desired deposit.

Fume Hood

The Fume Hood is often the primary control device for protecting laboratory workers when working with flammable and toxic chemicals. It is a type of local ventilation device that is designed to limit exposure to hazardous or toxic fumes, vapors or dusts .

The Fume Hood is often the primary control device for protecting laboratory workers when working with flammable and toxic chemicals. It is a type of local ventilation device that is designed to limit exposure to hazardous or toxic fumes, vapors or dusts .

The Fume Hood is often the primary control device for protecting laboratory workers when working with flammable and toxic chemicals. It is a type of local ventilation device that is designed to limit exposure to hazardous or toxic fumes, vapors or dusts .

The Fume Hood is often the primary control device for protecting laboratory workers when working with flammable and toxic chemicals. It is a type of local ventilation device that is designed to limit exposure to hazardous or toxic fumes, vapors or dusts .Centrifuge and Spin Coater

Centrifuge: Centrifuge is a machine with a rapidly rotating container that applies centrifugal force to its contents, typically to separate the denser material (e.g. graphite powder from water mixture) or liquids from solids.

Spin-coater: Spin coater is machine used for coating a material on a substrate by desired rotation speed. Rotation is continued while the fluid spins off the edges of the substrate, until the desired thickness of the film is achieved. The applied solvent is usually volatile, and simultaneously evaporates.

Centrifuge: Centrifuge is a machine with a rapidly rotating container that applies centrifugal force to its contents, typically to separate the denser material (e.g. graphite powder from water mixture) or liquids from solids.

Spin-coater: Spin coater is machine used for coating a material on a substrate by desired rotation speed. Rotation is continued while the fluid spins off the edges of the substrate, until the desired thickness of the film is achieved. The applied solvent is usually volatile, and simultaneously evaporates.

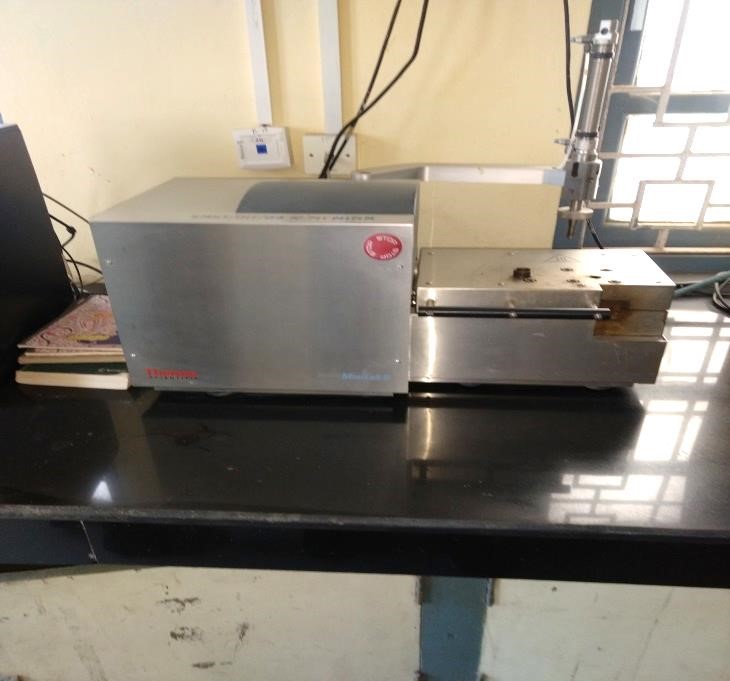

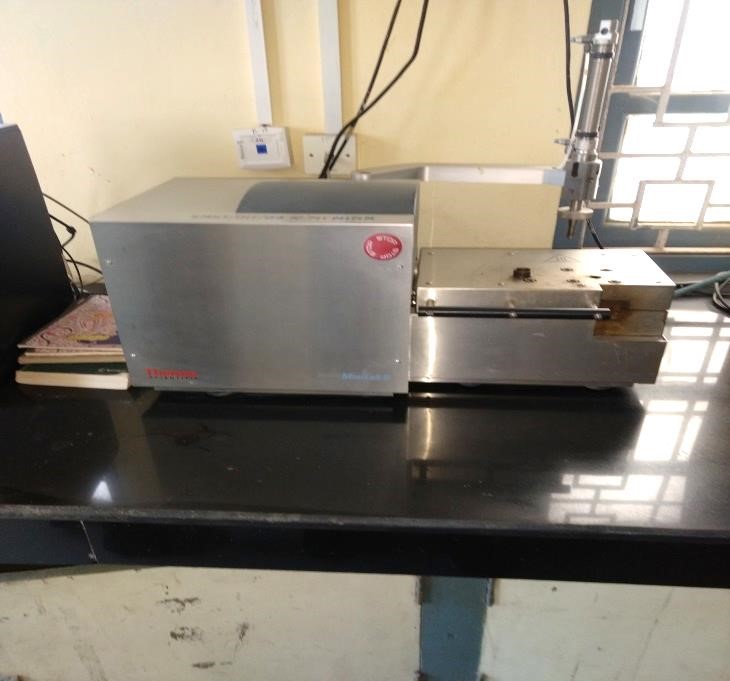

Fluorescence spectrophotometer

Fluorescence spectroscopy is a type of electromagnetic spectroscopy that analyses fluorescence from a sample. It involves using a beam of xenon lamp, in wavelength range 200nm to 900nm, that excites the electrons in molecules of certain compounds and causes them to emit light. Fluorescence spectroscopy is a rapid, sensitive method for characterizing molecular environments and events.

Fluorescence spectroscopy is a type of electromagnetic spectroscopy that analyses fluorescence from a sample. It involves using a beam of xenon lamp, in wavelength range 200nm to 900nm, that excites the electrons in molecules of certain compounds and causes them to emit light. Fluorescence spectroscopy is a rapid, sensitive method for characterizing molecular environments and events.

Fluorescence spectroscopy is a type of electromagnetic spectroscopy that analyses fluorescence from a sample. It involves using a beam of xenon lamp, in wavelength range 200nm to 900nm, that excites the electrons in molecules of certain compounds and causes them to emit light. Fluorescence spectroscopy is a rapid, sensitive method for characterizing molecular environments and events.

Fluorescence spectroscopy is a type of electromagnetic spectroscopy that analyses fluorescence from a sample. It involves using a beam of xenon lamp, in wavelength range 200nm to 900nm, that excites the electrons in molecules of certain compounds and causes them to emit light. Fluorescence spectroscopy is a rapid, sensitive method for characterizing molecular environments and events.

Plasma Surface Technology

The basic device consists of standard wiring, electrical components, tubing. The height of the basic device may vary with several additional options. Plasma is evenly distributed inside a plasma chamber. Chamber volume varies from 0.1 to 12,600 litre. Oxidation-sensitive objects can be cleaned with plasma. (e.g. H2 as process gas).

The basic device consists of standard wiring, electrical components, tubing. The height of the basic device may vary with several additional options. Plasma is evenly distributed inside a plasma chamber. Chamber volume varies from 0.1 to 12,600 litre. Oxidation-sensitive objects can be cleaned with plasma. (e.g. H2 as process gas).

The basic device consists of standard wiring, electrical components, tubing. The height of the basic device may vary with several additional options. Plasma is evenly distributed inside a plasma chamber. Chamber volume varies from 0.1 to 12,600 litre. Oxidation-sensitive objects can be cleaned with plasma. (e.g. H2 as process gas).

The basic device consists of standard wiring, electrical components, tubing. The height of the basic device may vary with several additional options. Plasma is evenly distributed inside a plasma chamber. Chamber volume varies from 0.1 to 12,600 litre. Oxidation-sensitive objects can be cleaned with plasma. (e.g. H2 as process gas).Spin Coating Instrument

Spin Coating is a standard laboratory procedure which involves depositing thin films of materials, often polymers and inorganic materials through solution process uniformly on flat substrates.

Spin Coating is a standard laboratory procedure which involves depositing thin films of materials, often polymers and inorganic materials through solution process uniformly on flat substrates.

Spin Coating is a standard laboratory procedure which involves depositing thin films of materials, often polymers and inorganic materials through solution process uniformly on flat substrates.

Spin Coating is a standard laboratory procedure which involves depositing thin films of materials, often polymers and inorganic materials through solution process uniformly on flat substrates.Keysight B2912A (I-V Source unit)

The Keysight B2912A Precision Source / Measure Unit (SMU) is a 2-channel, compact and cost-effective bench-top SMU with the capability to source and measure both voltage and current. It is versatile to perform I/V (current vs. voltage) measurement easily with high accuracy. Integration of 4 quadrant source and measurement capabilities enables I/V measurement simply and easily without configuring multiple instruments.

The Keysight B2912A Precision Source / Measure Unit (SMU) is a 2-channel, compact and cost-effective bench-top SMU with the capability to source and measure both voltage and current. It is versatile to perform I/V (current vs. voltage) measurement easily with high accuracy. Integration of 4 quadrant source and measurement capabilities enables I/V measurement simply and easily without configuring multiple instruments.

The wide coverage of 210 V, 3 A DC/10.5 A pulse with a single instrument minimizes the investment. Minimum 10 fA/100 nV measurement resolution support the accurate characterization of DUT. The superior 4.3’’ color display and various view modes improve productivity for the test, debug and characterization with intuitive operation.

The Keysight B2912A Precision Source / Measure Unit (SMU) is a 2-channel, compact and cost-effective bench-top SMU with the capability to source and measure both voltage and current. It is versatile to perform I/V (current vs. voltage) measurement easily with high accuracy. Integration of 4 quadrant source and measurement capabilities enables I/V measurement simply and easily without configuring multiple instruments.

The Keysight B2912A Precision Source / Measure Unit (SMU) is a 2-channel, compact and cost-effective bench-top SMU with the capability to source and measure both voltage and current. It is versatile to perform I/V (current vs. voltage) measurement easily with high accuracy. Integration of 4 quadrant source and measurement capabilities enables I/V measurement simply and easily without configuring multiple instruments.The wide coverage of 210 V, 3 A DC/10.5 A pulse with a single instrument minimizes the investment. Minimum 10 fA/100 nV measurement resolution support the accurate characterization of DUT. The superior 4.3’’ color display and various view modes improve productivity for the test, debug and characterization with intuitive operation.

Thermal Evaporation Deposition System

Thermal evaporation is a common method of physical vapour deposition (PVD). It is one of the simplest forms of PVD and typically uses a resistive heat source to evaporate a solid material in a vacuum environment to form a thin film. The material is heated in a high vacuum chamber until vapour pressure is produced. The evaporated material, or vapour stream, traverses the vacuum chamber with thermal energy and coats the substrate.

Thermal evaporation is a common method of physical vapour deposition (PVD). It is one of the simplest forms of PVD and typically uses a resistive heat source to evaporate a solid material in a vacuum environment to form a thin film. The material is heated in a high vacuum chamber until vapour pressure is produced. The evaporated material, or vapour stream, traverses the vacuum chamber with thermal energy and coats the substrate.

Thermal evaporation deposits both metals and non-metals, including aluminium (Al), gold (Au), Silver (Ag), Lithium fluoride (LiF) and Molybdenum oxides (MoO3). Thermal evaporation is used most commonly for applications involving electrical contacts, by depositing such single metals as silver or aluminium. More complex applications include the co-deposition of several components and can be achieved by carefully controlling the temperature of individual crucibles. Thermal evaporation can be applied to deposit metallic contact layers for thin film devices such as OLEDs, solar cells and thin-film transistors. To better achieve consistent, high-quality results, Denton Vacuum controls the rate of deposition using quartz crystal rate sensor, temperature or optical monitoring systems (OMS).

Thermal evaporation is a common method of physical vapour deposition (PVD). It is one of the simplest forms of PVD and typically uses a resistive heat source to evaporate a solid material in a vacuum environment to form a thin film. The material is heated in a high vacuum chamber until vapour pressure is produced. The evaporated material, or vapour stream, traverses the vacuum chamber with thermal energy and coats the substrate.

Thermal evaporation is a common method of physical vapour deposition (PVD). It is one of the simplest forms of PVD and typically uses a resistive heat source to evaporate a solid material in a vacuum environment to form a thin film. The material is heated in a high vacuum chamber until vapour pressure is produced. The evaporated material, or vapour stream, traverses the vacuum chamber with thermal energy and coats the substrate.Thermal evaporation deposits both metals and non-metals, including aluminium (Al), gold (Au), Silver (Ag), Lithium fluoride (LiF) and Molybdenum oxides (MoO3). Thermal evaporation is used most commonly for applications involving electrical contacts, by depositing such single metals as silver or aluminium. More complex applications include the co-deposition of several components and can be achieved by carefully controlling the temperature of individual crucibles. Thermal evaporation can be applied to deposit metallic contact layers for thin film devices such as OLEDs, solar cells and thin-film transistors. To better achieve consistent, high-quality results, Denton Vacuum controls the rate of deposition using quartz crystal rate sensor, temperature or optical monitoring systems (OMS).

Physical Property Measurement System

The Quantum Design DynaCool is an instrument designed to measure a variety of a sample’s physical properties while controlling the conditions experienced by the sample employing a minimum amount of condensed liquid Helium-4 for cooling both the sample chamber and superconducting magnet. It is equipped with a 9T conduction-cooled superconducting switch-less magnet system.

The Quantum Design DynaCool is an instrument designed to measure a variety of a sample’s physical properties while controlling the conditions experienced by the sample employing a minimum amount of condensed liquid Helium-4 for cooling both the sample chamber and superconducting magnet. It is equipped with a 9T conduction-cooled superconducting switch-less magnet system.

It offers to perform the DC magnetization measurements (VSM option) as a function of temperature/magnetic field in the range of 1.8-1000 K with sensitivity ⁓ 10-6 emu, AC magnetic susceptibility determination for frequencies between 10-10000 Hz and specific heat measurement in the temperature range 1.8-390 K. These studies allow us to establish the magnetic behavior of different materials and perform a detailed analysis of the nature of their phase transitions.

The Quantum Design DynaCool is an instrument designed to measure a variety of a sample’s physical properties while controlling the conditions experienced by the sample employing a minimum amount of condensed liquid Helium-4 for cooling both the sample chamber and superconducting magnet. It is equipped with a 9T conduction-cooled superconducting switch-less magnet system.

The Quantum Design DynaCool is an instrument designed to measure a variety of a sample’s physical properties while controlling the conditions experienced by the sample employing a minimum amount of condensed liquid Helium-4 for cooling both the sample chamber and superconducting magnet. It is equipped with a 9T conduction-cooled superconducting switch-less magnet system.It offers to perform the DC magnetization measurements (VSM option) as a function of temperature/magnetic field in the range of 1.8-1000 K with sensitivity ⁓ 10-6 emu, AC magnetic susceptibility determination for frequencies between 10-10000 Hz and specific heat measurement in the temperature range 1.8-390 K. These studies allow us to establish the magnetic behavior of different materials and perform a detailed analysis of the nature of their phase transitions.

Alpha-A High Performance Frequency Analyser

The Cryogen-Free High Field Measurement System combines the cryogen-free technology with sophisticated measurement techniques providing a versatile investigative device achieving low temperatures (⁓ 1.8 K) and high magnetic fields (7 T) without the use of liquid cryogens.

The Cryogen-Free High Field Measurement System combines the cryogen-free technology with sophisticated measurement techniques providing a versatile investigative device achieving low temperatures (⁓ 1.8 K) and high magnetic fields (7 T) without the use of liquid cryogens.

It is being used for measurement of dielectric response/pyroelectric current/ resistivity of materials as a function temperature with the help of Novocontrol/ Hioki LCR meter and Keithley electrometer/nanovoltmeter. These studies allow us to characterize dielectric behavior of materials to explore their scope in the electronic industry.

The Cryogen-Free High Field Measurement System combines the cryogen-free technology with sophisticated measurement techniques providing a versatile investigative device achieving low temperatures (⁓ 1.8 K) and high magnetic fields (7 T) without the use of liquid cryogens.

The Cryogen-Free High Field Measurement System combines the cryogen-free technology with sophisticated measurement techniques providing a versatile investigative device achieving low temperatures (⁓ 1.8 K) and high magnetic fields (7 T) without the use of liquid cryogens.It is being used for measurement of dielectric response/pyroelectric current/ resistivity of materials as a function temperature with the help of Novocontrol/ Hioki LCR meter and Keithley electrometer/nanovoltmeter. These studies allow us to characterize dielectric behavior of materials to explore their scope in the electronic industry.

18 KW Rotating Anode X-Ray Diffractometer

The RINT 2000/ PC series of Rigaku is an 18 kW rotating anode based powder X-ray diffractometer (XRD) using Cu K radiation with Bragg- Brentano geometry fitted with a graphite monochromator in the diffracted beam. This can record XRD patterns at standard room temperature,

The RINT 2000/ PC series of Rigaku is an 18 kW rotating anode based powder X-ray diffractometer (XRD) using Cu K radiation with Bragg- Brentano geometry fitted with a graphite monochromator in the diffracted beam. This can record XRD patterns at standard room temperature,

high temperatures (up to 1600 K) and low temperatures (up to 12 K). These studies enable us to perform structural analysis of crystalline materials in a wide temperature range and study their nature of structural phase transition.

The RINT 2000/ PC series of Rigaku is an 18 kW rotating anode based powder X-ray diffractometer (XRD) using Cu K radiation with Bragg- Brentano geometry fitted with a graphite monochromator in the diffracted beam. This can record XRD patterns at standard room temperature,

The RINT 2000/ PC series of Rigaku is an 18 kW rotating anode based powder X-ray diffractometer (XRD) using Cu K radiation with Bragg- Brentano geometry fitted with a graphite monochromator in the diffracted beam. This can record XRD patterns at standard room temperature,high temperatures (up to 1600 K) and low temperatures (up to 12 K). These studies enable us to perform structural analysis of crystalline materials in a wide temperature range and study their nature of structural phase transition.

TABLE TOP X-RD  X-ray is a powerful nondestructive technique for characterizing crystalline materials. It provides information on structures, phases, preferred crystal orientations (texture), and other structural parameters, such as average grain size, crystallinity, strain, and crystal defects.

X-ray is a powerful nondestructive technique for characterizing crystalline materials. It provides information on structures, phases, preferred crystal orientations (texture), and other structural parameters, such as average grain size, crystallinity, strain, and crystal defects.

X-ray is a powerful nondestructive technique for characterizing crystalline materials. It provides information on structures, phases, preferred crystal orientations (texture), and other structural parameters, such as average grain size, crystallinity, strain, and crystal defects.

X-ray is a powerful nondestructive technique for characterizing crystalline materials. It provides information on structures, phases, preferred crystal orientations (texture), and other structural parameters, such as average grain size, crystallinity, strain, and crystal defects.Cryogen Free Magnet System (CFMS):

The Cryogen-Free High Field Measurement System combines the cryogen-free technology with sophisticated measurement techniques providing a versatile investigative device achieving low temperatures (⁓ 1.8 K) and high magnetic fields (7 T) without the use of liquid cryogens. It is being used for measurement of dielectric response/pyroelectric current/ resistivity of materials as a function temperature with the help of Novocontrol/ Hioki LCR meter and Keithley electrometer/nanovoltmeter. These studies allow us to characterize dielectric behavior of materials to explore their scope in electronic industry.

The Cryogen-Free High Field Measurement System combines the cryogen-free technology with sophisticated measurement techniques providing a versatile investigative device achieving low temperatures (⁓ 1.8 K) and high magnetic fields (7 T) without the use of liquid cryogens. It is being used for measurement of dielectric response/pyroelectric current/ resistivity of materials as a function temperature with the help of Novocontrol/ Hioki LCR meter and Keithley electrometer/nanovoltmeter. These studies allow us to characterize dielectric behavior of materials to explore their scope in electronic industry.

The Cryogen-Free High Field Measurement System combines the cryogen-free technology with sophisticated measurement techniques providing a versatile investigative device achieving low temperatures (⁓ 1.8 K) and high magnetic fields (7 T) without the use of liquid cryogens. It is being used for measurement of dielectric response/pyroelectric current/ resistivity of materials as a function temperature with the help of Novocontrol/ Hioki LCR meter and Keithley electrometer/nanovoltmeter. These studies allow us to characterize dielectric behavior of materials to explore their scope in electronic industry.

The Cryogen-Free High Field Measurement System combines the cryogen-free technology with sophisticated measurement techniques providing a versatile investigative device achieving low temperatures (⁓ 1.8 K) and high magnetic fields (7 T) without the use of liquid cryogens. It is being used for measurement of dielectric response/pyroelectric current/ resistivity of materials as a function temperature with the help of Novocontrol/ Hioki LCR meter and Keithley electrometer/nanovoltmeter. These studies allow us to characterize dielectric behavior of materials to explore their scope in electronic industry.

UNIVERSAL TESTING MACHINE (UTM)

UTM is an instrument used to measure the mechanical properties like tensile strength, compressive strength, bending etc. of different kinds of samples (polymers, metals, ceramics...).

UTM is an instrument used to measure the mechanical properties like tensile strength, compressive strength, bending etc. of different kinds of samples (polymers, metals, ceramics...).

UTM is an instrument used to measure the mechanical properties like tensile strength, compressive strength, bending etc. of different kinds of samples (polymers, metals, ceramics...).

UTM is an instrument used to measure the mechanical properties like tensile strength, compressive strength, bending etc. of different kinds of samples (polymers, metals, ceramics...).EXTRUDER X-ray is a powerful nondestructive technique for characterizing crystalline materials. It provides information on structures, phases, preferred crystal orientations (texture), and other structural parameters, such as average grain size, crystallinity, strain, and crystal defects.

X-ray is a powerful nondestructive technique for characterizing crystalline materials. It provides information on structures, phases, preferred crystal orientations (texture), and other structural parameters, such as average grain size, crystallinity, strain, and crystal defects.

X-ray is a powerful nondestructive technique for characterizing crystalline materials. It provides information on structures, phases, preferred crystal orientations (texture), and other structural parameters, such as average grain size, crystallinity, strain, and crystal defects.

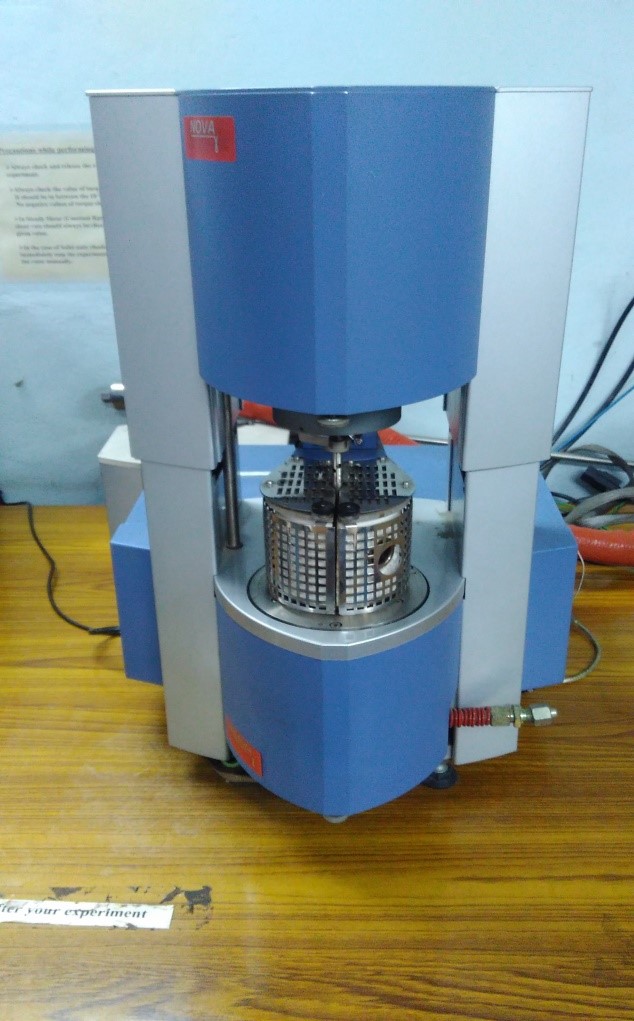

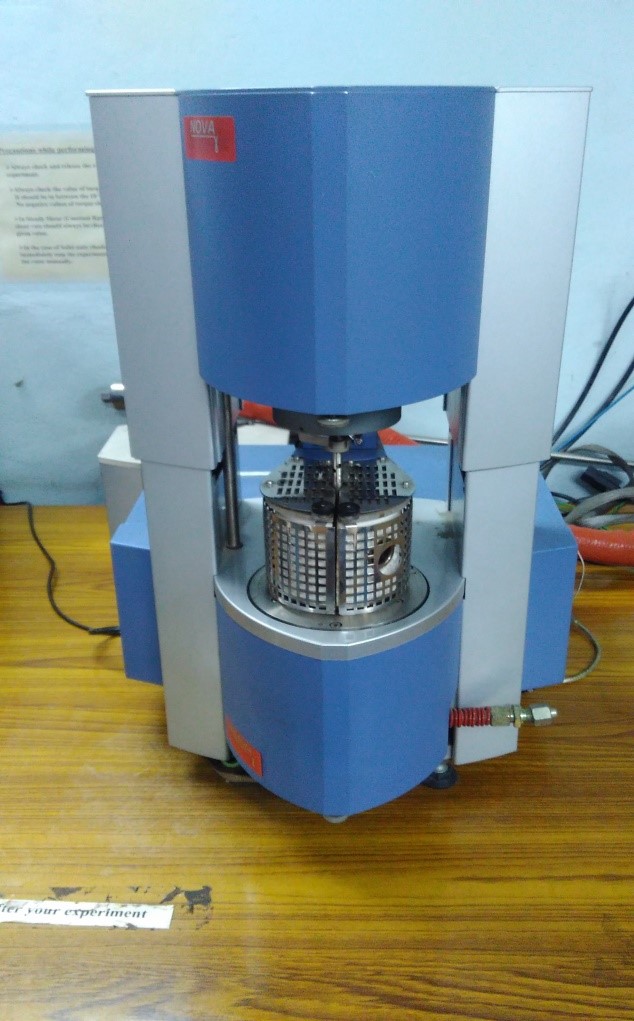

X-ray is a powerful nondestructive technique for characterizing crystalline materials. It provides information on structures, phases, preferred crystal orientations (texture), and other structural parameters, such as average grain size, crystallinity, strain, and crystal defects.RHEOMETER Rheometer is an instrument which are used to measure the rheological (flow and deformation of matter) properties of a material. It is capable of measuring viscosity and elasticity of a material in response to applied stress.

Rheometer is an instrument which are used to measure the rheological (flow and deformation of matter) properties of a material. It is capable of measuring viscosity and elasticity of a material in response to applied stress.

Rheometer is an instrument which are used to measure the rheological (flow and deformation of matter) properties of a material. It is capable of measuring viscosity and elasticity of a material in response to applied stress.

Rheometer is an instrument which are used to measure the rheological (flow and deformation of matter) properties of a material. It is capable of measuring viscosity and elasticity of a material in response to applied stress.

MICRO – INJECTOR

It is an instrument to observe the resistance of a material against a fixed load. It measures the permanent depth of indentation produced by a force/load on an indenter.

It is an instrument to observe the resistance of a material against a fixed load. It measures the permanent depth of indentation produced by a force/load on an indenter.

It is an instrument to observe the resistance of a material against a fixed load. It measures the permanent depth of indentation produced by a force/load on an indenter.

It is an instrument to observe the resistance of a material against a fixed load. It measures the permanent depth of indentation produced by a force/load on an indenter.HPLC: High-performance liquid chromatography or high-pressure liquid chromatography (HPLC) is a chromatographic method, used to separate a mixture of compounds in analytical chemistry and biochemistry so as to identify, quantify or purify the individual components of the mixture. HPLC works on the principle of the separation of the material according to their molecular weight and polarity. When a mixture of compounds is passed through the HPLC column, it gets separate into its components before it exits from the column.

High-performance liquid chromatography or high-pressure liquid chromatography (HPLC) is a chromatographic method, used to separate a mixture of compounds in analytical chemistry and biochemistry so as to identify, quantify or purify the individual components of the mixture. HPLC works on the principle of the separation of the material according to their molecular weight and polarity. When a mixture of compounds is passed through the HPLC column, it gets separate into its components before it exits from the column.

High-performance liquid chromatography or high-pressure liquid chromatography (HPLC) is a chromatographic method, used to separate a mixture of compounds in analytical chemistry and biochemistry so as to identify, quantify or purify the individual components of the mixture. HPLC works on the principle of the separation of the material according to their molecular weight and polarity. When a mixture of compounds is passed through the HPLC column, it gets separate into its components before it exits from the column.

High-performance liquid chromatography or high-pressure liquid chromatography (HPLC) is a chromatographic method, used to separate a mixture of compounds in analytical chemistry and biochemistry so as to identify, quantify or purify the individual components of the mixture. HPLC works on the principle of the separation of the material according to their molecular weight and polarity. When a mixture of compounds is passed through the HPLC column, it gets separate into its components before it exits from the column.DIFFERENTIAL SCANNING CALORIMETRY (DSC) DSC is a thermos-analytical technique in which the differences in the amount of heat required to

DSC is a thermos-analytical technique in which the differences in the amount of heat required to

increase the temperature of a sample and reference are measured as a function of temperature.

DSC analysis is used to measure melting temperature, heat of fusion, latent heat of melting, glass

transition temperature, crystalline phase transition temperature and energy, specific heat or heat

capacity.

DSC is a thermos-analytical technique in which the differences in the amount of heat required to

DSC is a thermos-analytical technique in which the differences in the amount of heat required toincrease the temperature of a sample and reference are measured as a function of temperature.

DSC analysis is used to measure melting temperature, heat of fusion, latent heat of melting, glass

transition temperature, crystalline phase transition temperature and energy, specific heat or heat

capacity.

THERMOGRAVIMETRIC ANALYSIS/DIFFERENTIAL THERMAL ANALYSIS

(TGA/DTA)

Thermogravimetric analysis (TGA) is a method of thermal analysis in which changes in physical

Thermogravimetric analysis (TGA) is a method of thermal analysis in which changes in physical

and chemical properties of materials are measured as a function of increasing temperature (with

constant heating rate), or as a function of time (with constant temperature and/or constant mass

loss). In DTA, the temperature difference between a substance and a reference material is

measured as a function of temperature while the substance and reference material are subjected

to a controlled temperature program.

(TGA/DTA)

Thermogravimetric analysis (TGA) is a method of thermal analysis in which changes in physical

Thermogravimetric analysis (TGA) is a method of thermal analysis in which changes in physicaland chemical properties of materials are measured as a function of increasing temperature (with

constant heating rate), or as a function of time (with constant temperature and/or constant mass

loss). In DTA, the temperature difference between a substance and a reference material is

measured as a function of temperature while the substance and reference material are subjected

to a controlled temperature program.

SPUTTERING DEPOSITION SYSTEM Sputtering is a versatile kind of physical vapour deposition (PVD) technique, which used to deposit various kind of thin films of a variety of materials (e.g. insulator, metal, alloy, ceramic, etc.) onto a wide range of material surfaces (a.k.a. “substrate”). The technique is based upon ion bombardment of a source material (a.k.a. “target”) in the presence of high vacuum through the process of momentum transformation.

Sputtering is a versatile kind of physical vapour deposition (PVD) technique, which used to deposit various kind of thin films of a variety of materials (e.g. insulator, metal, alloy, ceramic, etc.) onto a wide range of material surfaces (a.k.a. “substrate”). The technique is based upon ion bombardment of a source material (a.k.a. “target”) in the presence of high vacuum through the process of momentum transformation.

Sputtering is a versatile kind of physical vapour deposition (PVD) technique, which used to deposit various kind of thin films of a variety of materials (e.g. insulator, metal, alloy, ceramic, etc.) onto a wide range of material surfaces (a.k.a. “substrate”). The technique is based upon ion bombardment of a source material (a.k.a. “target”) in the presence of high vacuum through the process of momentum transformation.

Sputtering is a versatile kind of physical vapour deposition (PVD) technique, which used to deposit various kind of thin films of a variety of materials (e.g. insulator, metal, alloy, ceramic, etc.) onto a wide range of material surfaces (a.k.a. “substrate”). The technique is based upon ion bombardment of a source material (a.k.a. “target”) in the presence of high vacuum through the process of momentum transformation.