Our Department has following laboratories for conducting experiments at UG/ PG / Ph-D and research levels:

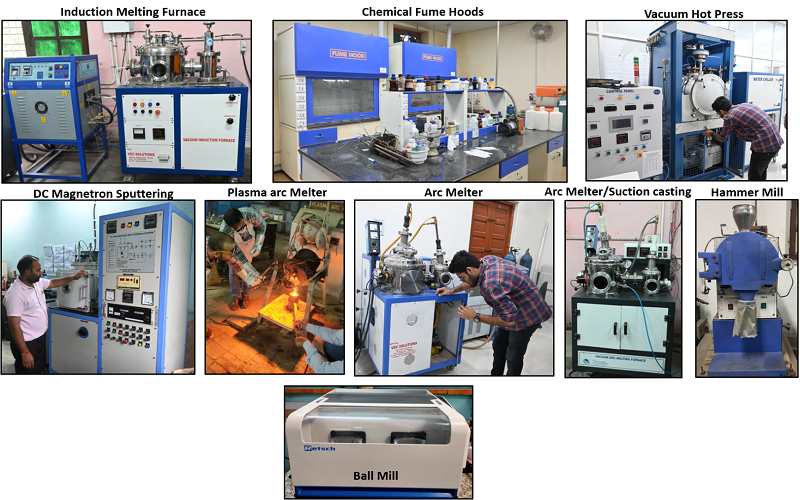

SYNTHESIS FACILITIES

The department has several melting, PVD and chemical synthesis facilities for making a variety of alloys, inorganic materials, powder metallurgy components.

| Equipment | Make & Model |

| Vacuum arc melting | VEC solutions, Bangalore |

| Vacuum induction melting | VEC solutions, Bangalore |

| Arc melting/suction casting | VEC solutions, Bangalore |

| Melt-spinning | Custom made |

| DC Magnetron sputtering | Vacuum industries Pvt. Ltd. |

| Ball mill | Retsch MM500, Mixer Mill |

| Vacuum hot pressing | VB ceramics, Chennai |

| Plasma arc melter | Custom made, 2.5 Kg capacity |

| Hammer mill | Ikon Instruments |

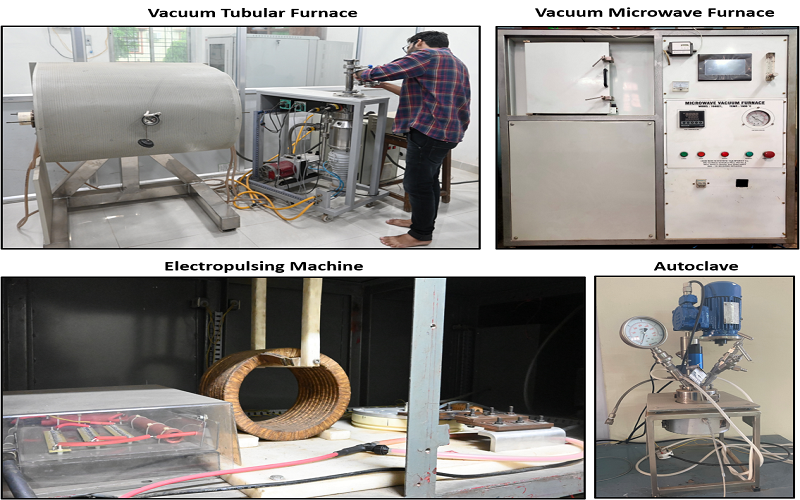

HEAT TREATMENT/SINTERING FACILITIES

Most metallurgical processes require various kinds of heat treatment for better properties. The following heat treatment facilities are currently present in the department

| Equipment | Model |

| Autoclave | Amar equipments Pvt. Ltd. |

| Vacuum microwave furnace | Omicron Scientific Equipment, Model: 160021 |

| Vacuum heat treatment tubular furnace | Custom made |

| Electropulsing machine | Custom made |

CHARACTERIZATION FACILITIES

Understanding the microstructural aspects of a material is key to analyzing the properties of any material. In this regard, characterization facilities ranging from optical to high end electron microscopes are present in the department.

| Equipment | Model |

| XRD | Panalytical Empyrean |

| Tabletop XRD | Rigaku Miniflex 600 |

| Optical microscope | Leica DM 1750 M |

| Scanning electron microscope | Quanta 200F |

| Transmission electron microscope | Tecnai G2T20 |

| Differential thermal analysis | Netzsch DSC 404 F3 Pegasus |

| Gas chromatography | Nucan 5700 |

| Drop calorimeter | MHTC 96 Line EVO, Setaram Instrumentation India |

| Atomic absorption spectrophotometer | ELICO – SL 168 |

MECHANICAL TESTING FACILITIES

A diverse range of testing facilities are available in the department to measure mechanical properties like strength, ductility, fatigue life etc.

| Equipment | Make & Model |

| Universal Testing Machine | Instron 100 kN |

| Corrosion Fatigue Machine | MTSTM Landmark Servo hydraulic test system (Model 370.10), 100kN |

| Fatigue Machine | MTS 50 kN (model: 312.21) |

| Pin on Disc Wear | Magnum Engineers, Bangalore |

| Ultrasonic Shotpeening | Sonats – Stress Voyager |

| Instrumented Indentation | AntonPaar |

| Rolling Mill | HILLE, Sheffield England, 50T capacity |

| Impression Creep Testing | Spranktronics, Bangalore, capacity – 1 kN |

| Izod Impact Testing | W & T Avery Ltd. |

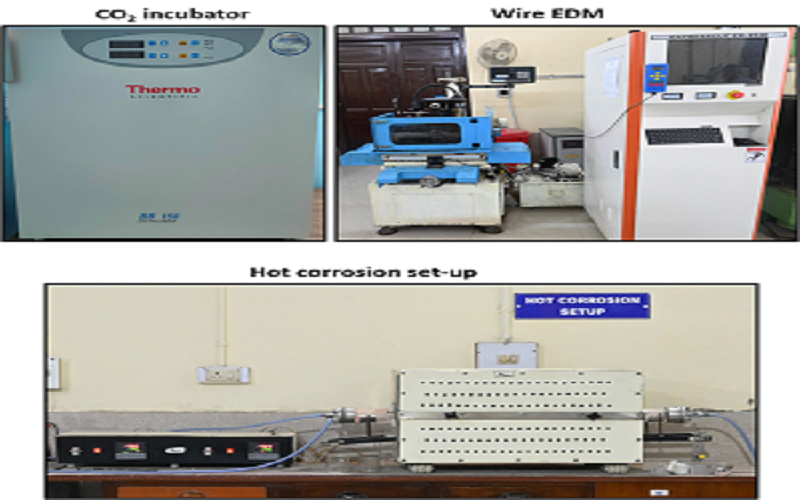

OTHER MAJOR FACILITIES

Apart from the mechanical property measurement set-ups, the department also possesses facilities to perform cell culture as well as corrosion studies.

| Equipment | Make and Model |

| CO2 incubator | Thermo scientific |

| Hot corrosion set-up | Two zone tube furnace, 1200°C, M/s Anil Scientific |

| Wire EDM | Expresscut EX-2530 |