Welcome to the Materials Modeling Lab (MML)

MML is a part of the Department of Metallurgical Engineering at Indian Institute of Technology (Banaras Hindu University), Varanasi . Our research interest lies in various aspects of Computational Thermodynamics like-(i) Experimental and DFT based thermochemical data, (ii) Cluster Variation Method and Cluster Expansion based Gibbs energy models, (iii) Developing algorithms and software for the phase diagram assessment optimization and (iv) Development of CALPHAD databases and their applications in novel materials and processes.

To this end, we develop novel computational thermodynamics tools to design alloys and materials. (see Research).

We are looking for passionate new PhD students, and Master students to join the team!

We are grateful for funding from IIT(BHU), Science and Engineering Research Board (SERB) and the Armaments Research Board (DRDO).

News

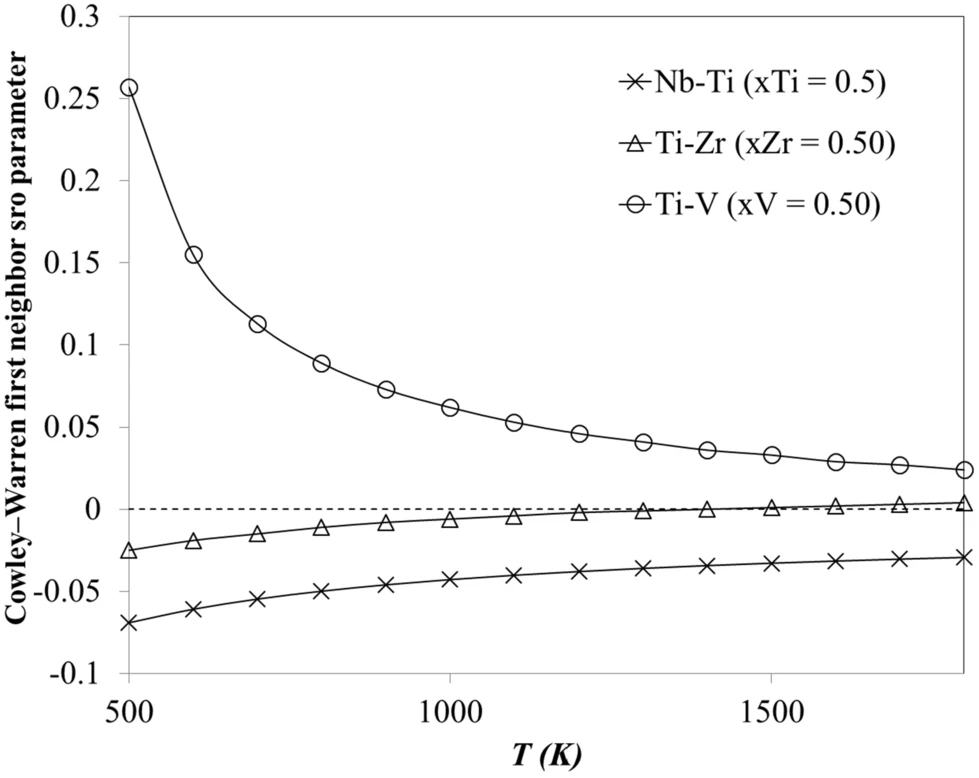

- Our latest #research on "Modeling Short-Range Ordering in Binary BCC Ti-X (X = Nb, V, Zr) Alloys using CE-CVM", published with @SpringerNature in "Journal of Phase Equilibria and Diffusion"

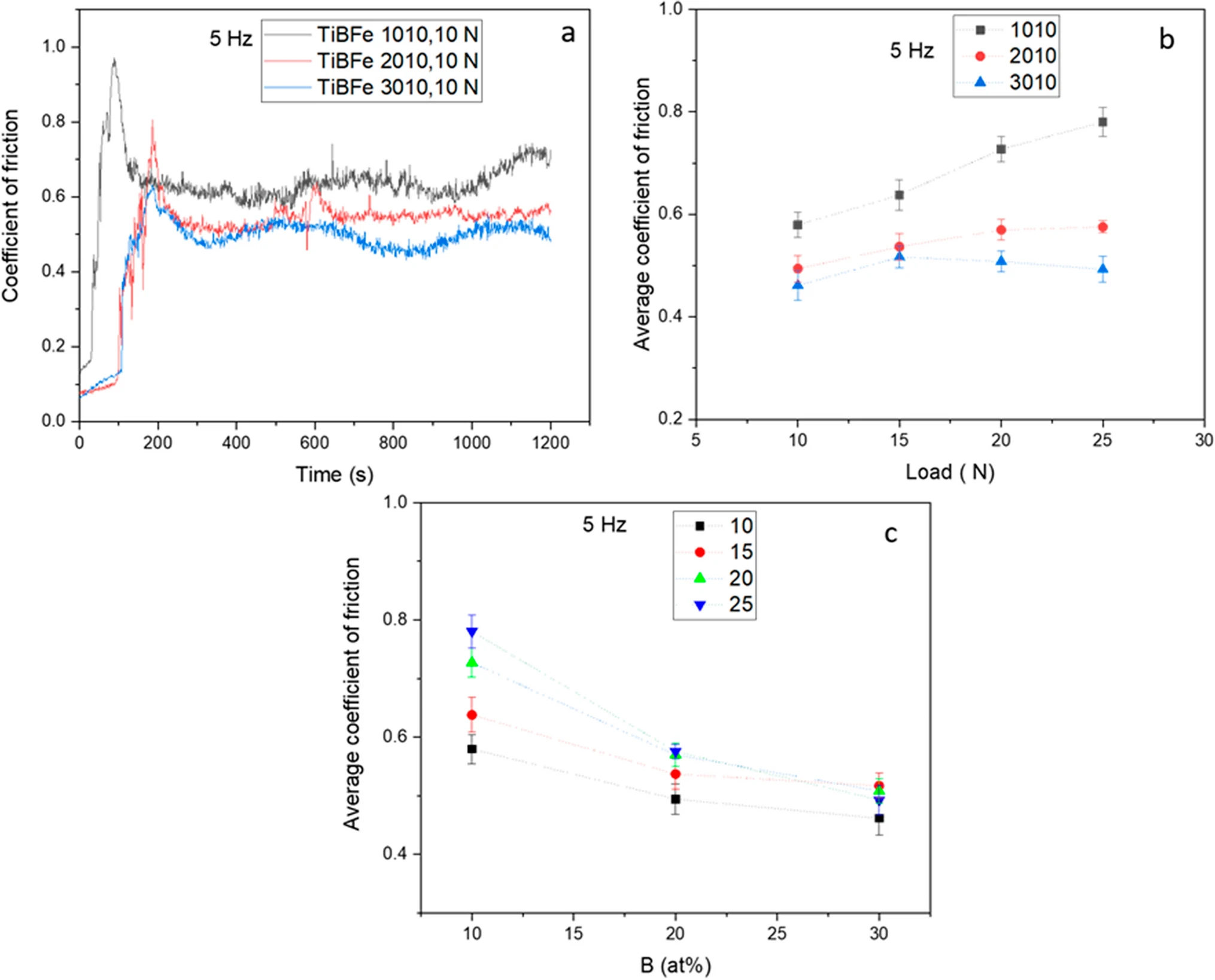

- Published paper on "Effect of Load on Tribological Properties of Ti–TiB–Fe Composites Processed via Spark Plasma Sintering (SPS)", Trans. IIM (2022).

- Published Paper on "First-principles calculations and thermodynamic assessment of the Nb–V system using CE-CVM", Calphad. 78 (2022) 102439.

-Published paper on "Reciprocating Wear of Ti-TiB In Situ Composites Synthesized via Vacuum Arc Melting", J. Mater. Eng. Perform. (2022).

- Published paper on "Thermodynamic Re-assessment of the Nb-Zr System Using the CE–CVM Model for Solid Solution Phases ", J. Phase Equilibria Diffus. (2022).

Research Areas

Our research interest lies in various aspects of Computational Thermodynamics:

- Experimental and DFT based thermochemical data.

- Cluster Variation Method and Cluster Expansion based Gibbs energy models.

- Developing algorithms and software for the phase diagram assessment optimization.

- Development of CALPHAD databases and their applications in designing novel materials and processes

More specifically, we are interested in:

- Titanium based systems

- Binary, ternary and multicomponent transition metal systems

- Compositionally complex alloys (CCA and HEA)

On-going Projects:

- Development of Functionally Graded Armor Composites (FGACs) Materials (2019-2022). This project is funded by DRDO Under Grant-in-Aid Scheme of ARMREB.

- Role of Short Range Ordering in designing High Entropy Alloys (2019-2022). This project is funded by Science and Engineering Research Board (SERB) under Core Research Grant.

- Development of low-cost β-Ti alloy for biomedical applications (2020-2023). This project is funded by Science and Engineering Research Board (SERB) under Core Research Grant. Role is Co-Principal Investigator

Completed Projects:

- Phase-diagrams and thermodynamic investigations of Ti-Hf-Zr system using cluster variation method (CVM) (2018-2020). This project was funded by IIT(BHU), Varanasi.

- Free energy minimization in binary alloy via genetic algorithms (2012). This project was funded by XI-Plan - Research Grant for New Faculty, University Grant Commission, India.

- Development of e-content on ancient Indian metallurgy and modern process metallurgy (2011-12). This project was funded by National Mission on Education through Information & Communication Technology (NMEICT), New Delhi.

Publications

Google Scholar Link: https://scholar.google.com/citations?user=IEVIvqEAAAAJ&hl=en

[1] S. Kumar, V. Jindal, Modeling Short-Range Ordering in Binary BCC Ti-X (X = Nb, V, Zr) Alloys using CE-CVM, J. Phase Equilibria Diffus. (2022). https://doi.org/10.1007/s11669-022-00989-y.

[2] A. Ranjan, V. Jindal, R. Tyagi, Effect of Load on Tribological Properties of Ti–TiB–Fe Composites Processed via Spark Plasma Sintering (SPS), Trans. Indian Inst. Met. (2022). https://doi.org/10.1007/s12666-022-02651-0.

[3] S. Kumar, V. Jindal, First-principles calculations and thermodynamic assessment of the Nb–V system using CE-CVM, Calphad. 78 (2022) 102439. https://doi.org/10.1016/j.calphad.2022.102439.

[4] A. Ranjan, R. Tyagi, V. Jindal, Reciprocating Wear of Ti-TiB In Situ Composites Synthesized via Vacuum Arc Melting, J. Mater. Eng. Perform. (2022). https://doi.org/10.1007/s11665-022-07002-0.

[5] S. Kumar, V. Jindal, Thermodynamic Re-assessment of the Nb-Zr System Using the CE–CVM Model for Solid Solution Phases, J. Phase Equilibria Diffus. (2022). https://doi.org/10.1007/s11669-022-00959-4.

[6] R.P. Gorrey, V. Jindal, B.N. Sarma, S. Lele, Thermodynamics of Binary bcc and fcc Phases for Exclusive Second-Neighbour Pair Interactions Using Cluster Variation Method: Analytical Solutions, Trans. Indian Inst. Met. (2022). https://doi.org/10.1007/s12666-021-02469-2.

[7] A.K. Thakur, R.P. Gorrey, V. Jindal, K. Muralidharan, A data-driven approach to approximate the correlation functions in cluster variation method, Model. Simul. Mater. Sci. Eng. 30 (2022) 015001. https://doi.org/10.1088/1361-651X/ac3a16.

[8] N. Joshi, M.K. Dash, C. Upadhyay, V. Jindal, P.K. Panda, M. Shukla, Physico-chemical characterization of kajjali, black sulphide of mercury, with respect to the role of sulfur in its formation and structure, J. Ayurveda Integr. Med. 12 (2021) 590–600. https://doi.org/10.1016/j.jaim.2021.05.006.

[9] R.P. Gorrey, V. Jindal, B.N. Sarma, S. Lele, Modification of Cluster Variation Method Entropy Functional for Binary fcc Phases using Tetrahedron Approximation, Trans. Indian Inst. Met. 74 (2021) 129–136. https://doi.org/10.1007/s12666-020-02119-z.

[10] R.P. Gorrey, V. Jindal, B.N. Sarma, S. Lele, Polynomial functions for configurational correlation functions in Gibbs energies of solid solutions using cluster variation method, Comput. Mater. Sci. 186 (2021) 109746. https://doi.org/10.1016/j.commatsci.2020.109746.

[11] A.K. Thakur, V.K. Pandey, V. Jindal, Calculation of Existence Domains and Optimized Phase Diagram for the Nb-Ti Binary Alloy System Using Computational Methods, J. Phase Equilibria Diffus. 41 (2020) 846–858. https://doi.org/10.1007/s11669-020-00843-z.

[12] A. Ranjan, R. Tyagi, V. Jindal, K.S.R. Chandran, Investigation on Wear Characteristics of TiBFe Composites Containing 10 at.% Boron and 10-30 at.% Iron, J. Mater. Eng. Perform. 29 (2020) 6333–6342. https://doi.org/10.1007/s11665-020-05130-z.

[13] R.P. Gorrey, V. Jindal, B.N. Sarma, S. Lele, Analytical solutions for the correlation functions of perfectly ordered binary phases based on bcc, fcc and cph structures using cluster variation method, Calphad. 71 (2020) 101773. https://doi.org/10.1016/j.calphad.2020.101773.

[14] J. Du, V. Jindal, A.P. Sanders, K.S. Ravi Chandran, CALPHAD-guided alloy design and processing for improved strength and toughness in Titanium Boride (TiB) ceramic alloy containing a ductile phase, Acta Mater. 171 (2019) 18–30. https://doi.org/10.1016/j.actamat.2019.03.040.

[15] V. Jindal, A. Sarda, A. Degnah, K.S. Ravi Chandran, Effect of iron & boron content on the Spark Plasma Sintering of Ti-B-Fe alloys, Adv. Powder Technol. 30 (2019) 423–427. https://doi.org/10.1016/j.apt.2018.11.021.

[16] J. Akram, P.R. Kalvala, V. Jindal, M. Misra, Evaluating location specific strain rates, temperatures, and accumulated strains in friction welds through microstructure modeling, Def. Technol. 14 (2018) 83–92. https://doi.org/10.1016/j.dt.2017.11.002.

[17] J. Du, A.P. Sanders, V. Jindal, K.S.R. Chandran, Rapid in situ formation and densification of titanium boride (TiB) nano-ceramic via transient liquid phase in electric field activated sintering, Scr. Mater. 123 (2016) 95–99. https://doi.org/10.1016/j.scriptamat.2016.06.010.

[18] V. Jindal, P.K.P. Rupa, G.K. Mandal, V.C. Srivastava, Effect of High-Temperature Severe Plastic Deformation on Microstructure and Mechanical Properties of IF Steel, J. Mater. Eng. Perform. 23 (2014) 1954–1958. https://doi.org/10.1007/s11665-014-0977-9.

[19] V. Jindal, B. Nageswara Sarma, S. Lele, An improved CVM entropy functional for binary fcc alloys, Comput. Mater. Sci. 84 (2014) 129–133. https://doi.org/10.1016/j.commatsci.2013.11.062.

[20] V. Jindal, B.N. Sarma, S. Lele, An improvement of cluster variation method entropy functional for bcc alloys, Calphad. 43 (2013) 48–51. https://doi.org/10.1016/j.calphad.2013.10.004.

[21] V. Jindal, B.N. Sarma, S. Lele, A thermodynamic assessment of the Cr–Mo system using CE-CVM, Calphad. 43 (2013) 80–85. https://doi.org/10.1016/j.calphad.2013.10.003.

[22] V.C. Srivastava, T. Singh, S. Ghosh Chowdhury, V. Jindal, S.G. Chowdhury, Microstructural Characteristics of Accumulative Roll-Bonded Ni-Al-Based Metal-Intermetallic Laminate Composite, J. Mater. Eng. Perform. 21 (2012) 1912–1918. https://doi.org/10.1007/s11665-011-0114-y.

[23] V. Jindal, V.C. Srivastava, V. Uhlenwinkel, On the role of liquid phase stability and GFA parameters, J. Non. Cryst. Solids. 355 (2009) 1552–1555. https://doi.org/10.1016/j.jnoncrysol.2009.05.049.

[24] V.C.C. Srivastava, V. Jindal, V. Uhlenwinkel, K. Bauckhage, Hot-deformation behaviour of spray-formed 2014 Al+SiCp metal matrix composites, Mater. Sci. Eng. a-Structural Mater. Prop. Microstruct. Process. 477 (2008) 86–95. https://doi.org/10.1016/j.msea.2007.06.086.

[25] V. Jindal, V.C.C. Srivastava, Growth of intermetallic layer at roll bonded IF-steel/aluminum interface, J. Mater. Process. Technol. 195 (2008) 88–93. https://doi.org/10.1016/j.jmatprotec.2007.04.118.

[26] V. Jindal, V.C. Srivastava, R.N. Ghosh, Development of IF steel–Al multilayer composite by repetitive roll bonding and annealing process, Mater. Sci. Technol. 24 (2008) 798–802. https://doi.org/10.1179/174328406X148688.

[27] V. Rajinikanth, V. Jindal, V.G. Akkimardi, M. Ghosh, K. Venkateswarlu, Transmission electron microscopy studies on the effect of strain on Al and Al-1% Sc alloy, Scr. Mater. 57 (2007) 425–428. https://doi.org/10.1016/j.scriptamat.2007.04.038.

[28] V. Jindal, P.K. De, K. Venkateswarlu, Effect of Al3SC precipitates on the work hardening behavior of aluminum-scandium alloys, Mater. Lett. 60 (2006) 3373–3375. https://doi.org/10.1016/j.matlet.2006.03.017.

[29] V. Jindal, V.C. Srivastava, A. Das, R.N. Ghosh, Reactive diffusion in the roll bonded iron–aluminum system, Mater. Lett. 60 (2006) 1758–1761. https://doi.org/10.1016/j.matlet.2005.12.013.

Lab facilities

| Computer Server- Processor configuration : Intel Xeon Gold 6140 (2.30GHz/18-core/24.75MB/140W) RAM size : 384 GB Type of Hard Disc Drive : NL SAS Hard disc drive Capacity : 8000 GB |

|

|

Vacuum Arc furnace with Suction Casting- Vacuum arc melting furnace with a Vacuum Suction Casting mechanism. Such a unique feature can produce cast products ( 6mm Dia. rod shape, up to 30g) by drawing the molten metal into the bottom cold copper casting mold. The sucking force applied results in a fast-moving and cause the rapid solidification of the melt which is ideal for reducing the shrinkage cavity defects. The machine also features a built-in mechanical manipulator for tilting and rotating metal ingots if the re-smelting process is needed. The SS304 chamber ensures a clean and healthy atmosphere suitable for the most demanding experimental requirements. |

| High vacuum high temperature heat treatment furnace- The furnace chamber is made out of SS 304 L material. it is a cylindrical chamber of size ID 100mm x 135mm shell length approx. The temperature accuracy ±5°C in the effective hot zone above 600°C, spare heating element 2 in nos and ultimate vacuum 5*10^-6 mbar.The equipment is Horizontally mounted, front loading cold walled type high vacuum furnace with double walled stainless steel vacuum chamber. the minimum attainable temperature and continuous operating temperature 1600°C. |

|

|

Vacuum Hot Press: The 20-ton capacity Vacuum Hot Press suitable for the sintering of sintering metal (Ti, Fe and Mo) and ceramic powders (TiB2) under controlled atmosphere and temperature conditions. |

| Planetary ball mill- new planetary mill has been developed by VBCC to pulverize the hard ceramic materials to fine particles. This mill may used for wet and dry grinding operations. and specifications are - QUANTITY - 20 (Min) to 100 (Max) Grams, MAXIMUM LOAD - 100 grams, INPUT SIZE - upto 0.1mm , OUT PUT SIZE - Less than 100 nanometers , OPTIMUM TIME - 4 to 6 Hours , MOTOR - 0.5HP/AC/Three phase , OPERATION - Through variable frequency drive , RPM - 300RPM (optimum speed – 250 to 300). |

|

Courses

1. Computational Methods for Metallurgy

2. Computer Applications in Metallurgy Practical

3. Modeling and Simulation in Metallurgy

4. Heat Treatment

Group Leader

Dr. Vikas Jindal

Associate Professor

e-mail: vjindal.met@iitbhu.ac.in

Phone No: 7081-268

Current Students

Shanker Kumar (Ph.D. Student)

e-mail:shankerkr.rs.met17@itbhu.ac.in

Phone No: +918210209823

M.Tech: Indian Institute of Technology, Kharagpur

Area of Interest: High Entropy Alloys, Iron and Steel Making, Computational Thermodynamics.

Padiri Murali (Ph.D. Student)

e-mail:murali.jrf.met21@iitbhu.ac.in

Phone No: +919666919807

M.Tech: Sri Venkateswara University Tirupati,Andhrapradesh

Area of Interest: Functionally Graded Armor Composite Materials

Ishu Yadav (Ph.D. Student)

e-mail: ishuyadav.rs.met20@itbhu.ac.in

Phone No: +917088785595

M.Tech: Indian Institute of Technology, (BHU)

Area of Interest: Computational Thermodynamics, First Principle Calculation, Beta-Titanium Alloys.

Akash Patle (M.Tech Student)

Area of Interest: Computational Thermodynamics, First Principle Calculation

Former Students

- Ankur Verma , M.Tech (2009-2011)

- Shivam Upadhyay, M.Tech (2010-2012)

Thesis Topic: Computation Thermodynamics of Au-Pt and Pd-Pt Phase Diagrams using Cluster Variation Method.

- Abhinav Jain , M.Tech (2010-2012)

Thesis Topic: Computation of Optimized Hf-Ti and Y-Zr Phase Diagrams Using Cluster Variation Method.

- Vasu Shreyasi, M.Tech (2011-2013)

Thesis Topic:Calculation of optimized Mo-Ti phase diagram using CVM.

- Vikas Sharma, M.Tech (2011-2013)

Thesis Topic: Computation of Optimized Ti-V Phase Diagram Using CE-CVM Method.

- M. Manikandan, M.Tech (2011-2013)

Thesis Topic: Computation of optimized phase diagram of Cr-W system using cluster variation method.

- Vivek Kumar Pandey, M.Tech (2011-2013)

Thesis Topic: Computation of Optimized Nb-Ti Phase Diagram using CE-CVM Method.

- Baibhab Dev, M.Tech (2012-2014)

Thesis Topic: Computational Thermodynamics of Ta-Ti and Nb-Ti Binary Systems using the Cluster Variation Method and Modified-Cluster Variation Method.

- Abhishek Kumar Thakur, M.Tech (2016-2018)

Thesis Topic:Thermodynamic reassessment of Nb-Ti alloy system using computational methods.

- Naveen Kumar, M.Tech (2017-2019 )

Thesis Topic: Re-Assessments of Ta-Zr and Ta-Ti Binary Sub-Systems Assisted by Ab-initio Calculations.

- Ishu Yadav, M.Tech (2017-2019 )

Thesis Topic: Thermodynamic re-assessments of Ti-Zr And Nb-Zr binary sub-systems assisted by Ab- initio calculations.

- Bidipta Dam, M.Tech (2018-2020 )

Thesis Topic: Development of Ti-Fe-Sn alloy as an affordable orthopaedic bio-implant material.

- Albert Linda, M.Tech (2018-2020 )

Thesis Topic: CALPHAD assisted designing of Al-Si alloys based phase change materials for thermal energy storage.

- Anil Prasad, M.Tech (2018-2020 )

Thesis Topic: First principle study of mechanical properties of material for biomedical applications.

Contact us

| Office: Ground floor, Room No: 034, Department of Metallurgical Engineering, Indian Institute of Technology (BHU) Varanasi Uttar Pradesh (India),221005 e-mail: vjindal.met@iitbhu.ac.in Phone No: 7081-268 |